When it comes to naval systems integration, not all enclosures are created equal. Mission-critical electronics demand protection from not just the sea—but from shock, vibration, EMI/RFI interference, and environmental extremes. That’s where standards like MIL-STD-901E, MIL-STD-167-1A, MIL-STD-461, and MIL-STD-810F come into play.

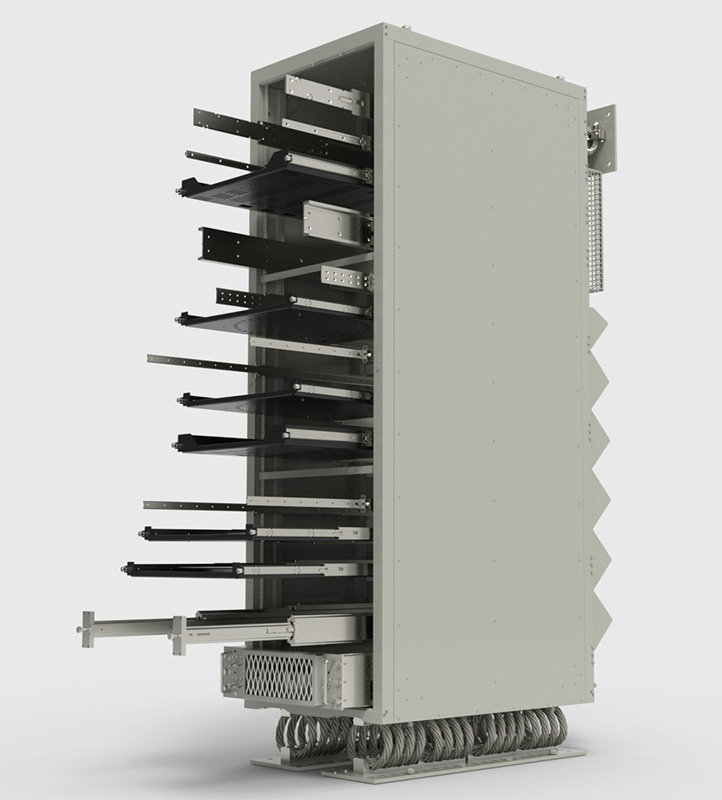

Electromet’s rugged enclosures and 19″ EIA racks are designed and tested to meet these stringent requirements, ensuring long-term operational reliability in mission-critical applications. Let’s explore what each of these standards entails and how Electromet aligns its designs to comply with them.

MIL-STD-901E: High-Impact Mechanical Shock

MIL-STD-901E addresses high-impact mechanical shock, particularly those experienced during combat scenarios or operational hazards such as underwater explosions or collisions. Qualification under this standard involves testing enclosures on floating barges where they are subjected to explosive charges to simulate shock pulses.

Electromet’s enclosures undergo both lightweight and heavyweight shock testing. For lightweight shock testing, typically performed on components under 200 pounds, shock machines or hammer blow testing may be used. For heavyweight items, full barge tests are conducted. Racks and enclosures are evaluated based on their structural integrity and continued function of internal equipment post-shock.

Key design considerations include:

- Welded steel or aluminum construction with high-tensile-strength fasteners

- Internal bracing and mechanical isolation of subcomponents

- Shock mounts rated for specific load and resonance characteristics

- Reinforced mounting interfaces for shipboard deck or bulkhead installation

MIL-STD-167-1A: Mechanical Vibration

Where MIL-STD-901E addresses discrete shock events, MIL-STD-167-1A covers continuous mechanical vibration caused by shipboard propulsion systems, rotating equipment, and environmental motion.

Type I (environmental vibration) testing simulates shipboard vibration conditions using variable frequency ranges (typically 4 to 33 Hz) with amplitudes defined by displacement or acceleration. Equipment must continue to operate without performance degradation throughout endurance testing periods.

Class 3 enclosures and subassemblies must:

- Modal analysis and finite element modeling (FEM) to identify and reinforce potential resonant points

- Use of damping materials, floating subframes, and tuned isolation systems

- Vibration-rated fasteners and locking mechanisms

MIL-STD-461: Electromagnetic Interference

This standard defines the electromagnetic compatibility (EMC) requirements for equipment and subsystems. It addresses both emissions and susceptibility across a range of frequencies. Equipment that fails to comply can generate interference, degrade system performance, or create vulnerabilities.

Electromet’s shielded enclosures meet MIL-STD-461 by incorporating:

- Conductive gasketing on all panel interfaces and doors

- EMI filters on power and signal lines

- Shielded ventilation filters

- Bonded metal surfaces to reduce potential gaps

Shielding effectiveness is validated through lab testing, including TEMPEST testing when required, and verified using network analyzers and EM field probes.

MIL-STD-810F: Environmental Conditions

Finally, MIL-STD-810F addresses environmental durability. It specifies test methods for temperature extremes, humidity, sand and dust ingress, salt fog, icing, and more. It is particularly relevant for open-deck or coastal installations.

To meet 810F requirements, Electromet uses:

- Powder-coated or anodized finishes with salt-spray resistance

- IP-rated gasketing for ingress protection (typically IP65+)

- Corrosion-resistant hardware and coatings per MIL-DTL-5541 or equivalent

- Environmental seals for cable pass-throughs

The Electromet Advantage

Unlike generic suppliers, Electromet provides traceable, documented compliance for each enclosure built to these standards. Our in-house test capabilities, materials engineering, and military heritage allow us to produce naval-grade enclosures that survive in theater.

If your program demands survivability, shielding, and compliance with defense standards, Electromet’s rugged enclosures are mission-ready.