MIL-STD-167, the military standard for vibration testing, is a cornerstone of ensuring the reliability and operational survivability of systems aboard naval vessels. This standard evaluates the resilience of equipment against mechanical and environmental vibrations that can originate from propulsion systems, weapons fire, and operational sea conditions. These vibrations, if unmitigated, can cause resonance frequencies in the range of 5 to 500 Hz, which are particularly dangerous for sensitive electronics. Prolonged exposure to such frequencies can lead to fatigue failures, circuit disruptions, and even complete system inoperability.

For mechanical packaging engineers, understanding how vibration affects electronics is critical. For example, many circuit boards exhibit failure when exposed to vibrations in the lower range of this spectrum due to the amplification of resonant modes. Attenuation through vibration isolation or enclosure design is essential to dampen these frequencies, ensuring that systems such as C4ISR (Command, Control, Communications, Computers, Intelligence, Surveillance, and Reconnaissance) platforms and Position, Navigation, and Timing (PNT) systems remain functional during demanding naval operations.

Electromet Enclosures and MIL-STD-167 Compliance

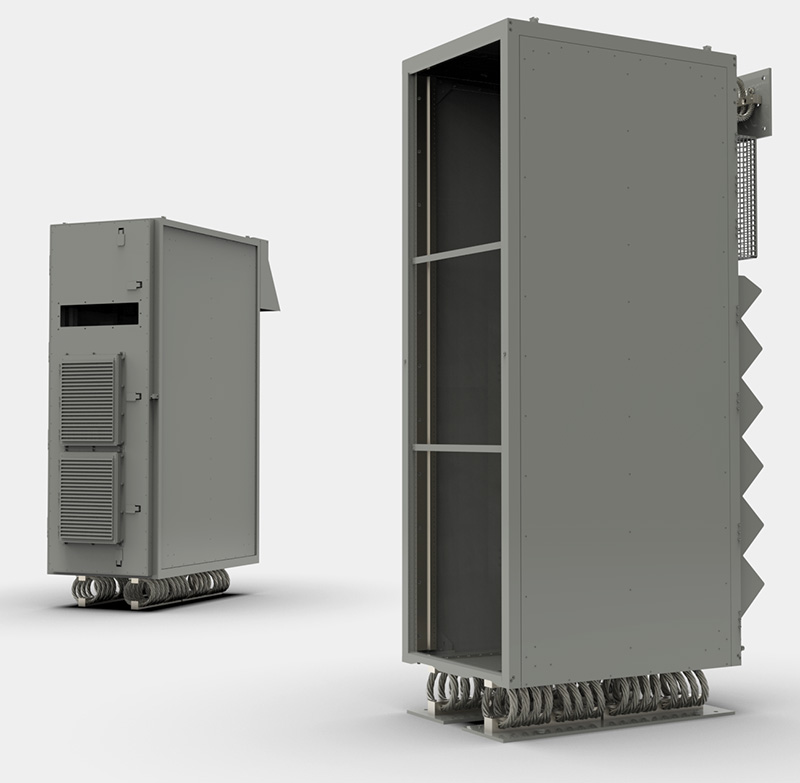

Electromet’s enclosures are specifically designed to address the vibration challenges outlined in MIL-STD-167, ensuring the survivability of mission-critical systems. With a focus on durability and customization, Electromet provides naval racks, cabinets, and naval enclosures that protect sensitive equipment from operational vibrations.

Electromet’s shock and vibration qualified enclosures incorporate advanced materials and engineering techniques to mitigate vibration-induced failures. These enclosures are designed to house electronics system stacks, ensuring reliable operation even in extreme vibration conditions.

Electromet offers modular enclosures that can be configured for various applications, including single-bay and multi-bay cabinet configurations. This modularity makes them ideal for housing equipment such as COTS and rugged servers, naval server storage, and electronic and kinetic weapons systems.

EMI/RFI Shielding and Naval Durability

In addition to vibration resistance, Electromet enclosures feature EMI/RFI shielding, protecting electronics from electromagnetic interference common in naval environments. Their mil-spec welding, mil-spec painting, and mil-spec finishing ensure longevity, even in harsh maritime conditions.

Collaboration Between Electromet and IDC Engineers

Electromet’s commitment to vibration resilience extends through their partnership with Isolator Dynamics Corporation (IDC), a leader in vibration isolation systems. This collaboration allows both companies to leverage their expertise in creating thorough solutions for the most challenging vibration requirements.

Custom Vibration Isolation Assemblies

Electromet and IDC engineers work together to design specialized vibration isolation assemblies tailored to the unique demands of naval shipboard electronics platforms. For example, they develop systems to isolate payloads from deck-mounted vibrations or mitigate harmonic disturbances caused by onboard machinery. These assemblies can be tuned to target specific vibration frequencies, ensuring optimal protection for enclosed equipment.

Co-Engineering Solutions

The collaboration begins with a thorough analysis of the equipment and its operating environment. Electromet engineers define the mechanical packaging and structural requirements of the enclosure, while IDC engineers design isolators to attenuate vibrations without compromising the enclosure’s stability or operational performance. For instance, in projects involving GEOINT systems or electronic warfare equipment, this co-engineering approach ensures that enclosures not only meet MIL-STD-167 but exceed customer expectations.

Meeting Diverse Vibration Requirements

IDC’s expertise in isolator design enables them to address a wide range of vibration profiles. Whether protecting rugged PDUs or large-scale multi-bay naval cabinets, the partnership ensures solutions tailored to payload weights, frequency ranges, and damping requirements. The result is a seamless integration of vibration isolation technology with Electromet’s enclosure designs.

Specialized Features of Electromet Enclosures

Electromet enclosures are designed to address the multifaceted challenges of naval operations, ensuring compliance with MIL-STD-167 and beyond.

Hatchable and Mechanically-Fastened Designs

Electromet’s hatchable and mechanically-fastened enclosures allow for quick assembly and disassembly in confined spaces aboard ships. This feature is particularly valuable for maintaining equipment such as naval server storage and C4ISR systems.

Durable Finishing for Naval Environments

With mil-spec finishing and coatings designed to withstand harsh maritime conditions, Electromet enclosures provide long-lasting protection for sensitive electronics. This durability is vital for applications such as PNT systems and naval electronic warfare.

Educating Engineers on Vibration Mitigation

For engineers designing systems for naval applications, vibration mitigation is not just a mechanical challenge but a mission-critical necessity. Understanding that frequencies between 5 and 500 Hz can amplify system resonances highlights the importance of using vibration isolation. Collaborations like that between Electromet and IDC demonstrate how integrating engineering disciplines can provide innovative solutions to ensure equipment survivability.

The Role of Attenuation in Operational Success

Effective attenuation systems reduce the amplitude of vibrations transmitted to electronic components, preventing the resonance that can cause mechanical fatigue or electrical malfunctions. Engineers must prioritize the inclusion of isolation systems in enclosure designs, particularly for systems exposed to consistent vibrational forces, such as those in naval shipboard electronics platforms.

Customer Benefits of Electromet’s MIL-STD-167 Solutions

Electromet’s comprehensive approach to vibration mitigation, including their partnership with IDC, delivers tangible benefits to customers.

Enhanced Equipment Survivability

By addressing vibration challenges head-on, Electromet ensures the reliability of mission-critical systems, from COTS servers to electronic and kinetic weapons systems.

Reduced Downtime and Maintenance Costs

The integration of IDC isolators with Electromet enclosures reduces wear and tear on sensitive electronics, lowering maintenance costs and improving system uptime.

Custom Solutions for Complex Needs

The collaboration between Electromet and IDC allows for the development of tailored solutions that meet the most demanding vibration requirements, ensuring customer satisfaction across diverse applications.

Conclusion

MIL-STD-167 is a vital standard for ensuring the reliability of naval systems in vibration-prone environments. Electromet’s enclosures, designed in collaboration with IDC, provide industry-leading solutions to meet these stringent requirements. By combining modular designs, EMI/RFI shielding, and custom vibration isolation assemblies, Electromet ensures the operational survivability of mission-critical systems, from PNT equipment to naval electronic warfare platforms.

For mechanical packaging engineers, the lessons from MIL-STD-167 highlight the importance of integrating vibration mitigation strategies. Electromet and IDC’s partnership exemplifies how engineering collaboration can deliver innovative, reliable, and mission-ready solutions for the most demanding naval applications.